-

Products

-

Services

Home - Industrial Efficiency - Diesel Craft Fuel Systems

In industries where every minute of downtime costs money, fuel quality is not optional—it’s critical. Diesel craft fuel systems are designed to filter contaminants, improve combustion, and extend engine life. In 2025, businesses that adopt advanced fuel management solutions are seeing measurable improvements in productivity, cost savings, and sustainability.

According to the U.S. Department of Energy, contaminated diesel fuel can lower efficiency by up to 20% and increase maintenance costs by 30–40%. For companies running fleets, heavy-duty generators, or manufacturing equipment, this loss adds up to millions annually.

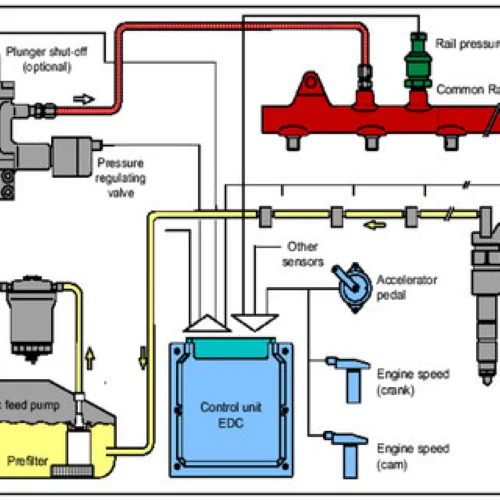

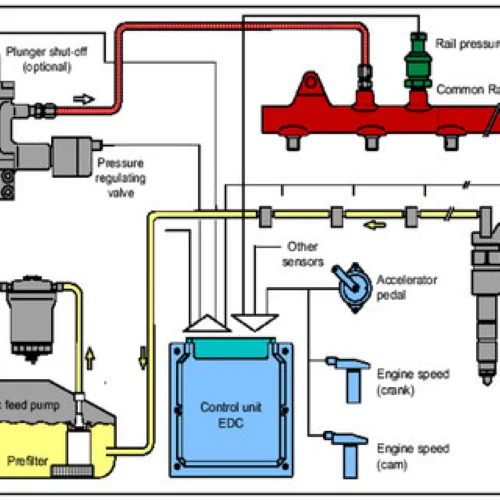

Diesel craft fuel systems filter out water, dirt, and microbial growth—common contaminants in storage tanks. Clean fuel ensures smoother combustion, fewer clogged injectors, and reduced black smoke emissions.

Engines running on filtered fuel consume less. A study by Fleet Owner Magazine reports a 5–8% improvement in fuel economy when high-performance filtration systems are used.

Fuel injectors and pumps are among the most expensive engine components. Protecting them from dirty fuel reduces emergency repairs and extends service intervals—cutting maintenance expenses by 25% or more.

Industrial operators can monitor fuel cleanliness and system performance. This prevents unexpected breakdowns, helping businesses plan maintenance instead of reacting to failures.

Machines, trucks, and generators that operate on consistently clean fuel can deliver 30–50% longer service life. That translates into fewer replacements and a stronger ROI on capital assets.

In 2025, industries cannot afford inefficiency. Diesel craft fuel systems are no longer “add-ons”—they are strategic investments. For companies aiming to reduce costs, improve efficiency, and extend asset life, the choice is clear.

Storage tanks, condensation, and microbial growth introduce water and dirt, which reduce performance.

Depending on usage, filters should be inspected every 250–500 hours of operation or as recommended by your supplier.

Yes, by ensuring complete combustion and preventing injector clogging, they improve efficiency by 5–8%.

Absolutely—most businesses recover the investment in 12–18 months through savings in fuel and maintenance.

Yes, even smaller fleets or workshop equipment see cost reductions and improved reliability.